What is Reliable and High-Quality PCB Fabrication and Assembly Services

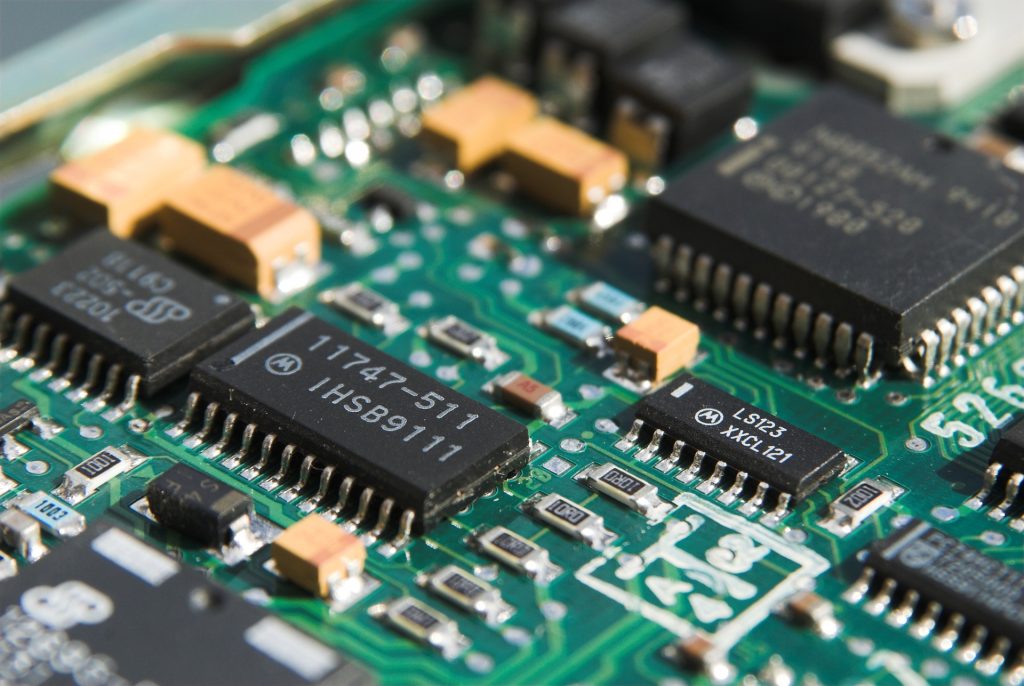

Reliable and high-quality PCB fabrication and assembly services refer to a set of processes and techniques that ensure that a printed circuit board (PCB) is manufactured and assembled to meet the highest standards of quality, reliability, and functionality. This includes using high-quality materials, precise manufacturing processes, accurate component placement and soldering, thorough testing, and quality control measures.

Reliable and high-quality PCB fabrication and assembly services ensure that the final product is durable, long-lasting, and performs as intended. They are essential for a wide range of industries and applications, including aerospace, medical devices, telecommunications, and consumer electronics.

By choosing a reliable and high-quality PCB fabrication and assembly service, customers can expect to receive a product that meets their design requirements and performs as expected. This reduces the risk of product failure, improves the product’s overall reliability, and can save time and money in the long run.

A Good PCB Fabrication And Assembly

A good PCB fabrication and assembly process involves several key factors to ensure that the final product is of high quality, reliable, and meets the project’s requirements. Here are some key characteristics of a good PCB fabrication and assembly process:

High-Quality Materials: The quality of the materials used in the fabrication and assembly process is critical to the reliability and longevity of the PCB. The substrate material should be of high quality, such as FR4, and the copper foil should be of a suitable thickness and purity. The solder mask should be applied uniformly and accurately to provide a protective layer against environmental factors such as moisture, dust, and debris.

Precise Manufacturing Process: The PCB fabrication process involves several steps, including drilling, etching, plating, and applying the solder mask. Each step should be carried out with precision to ensure that the final product meets the design requirements. For example, the drilling process must be carried out accurately to ensure that the holes are in the correct location and that the plated through-holes have a good connection.

Accurate Assembly: The components should be assembled accurately and in accordance with the design requirements. This means that the correct components must be used, they must be placed in the correct orientation, and they must be soldered correctly. The soldering process should be carried out at the appropriate temperature and for the appropriate length of time to ensure a good connection.

Thorough Testing: The finished PCB should be tested thoroughly to ensure that it meets the design requirements. This includes checking for continuity, verifying the accuracy of the placement of components, and checking the functionality of the board. Various testing methods can be used, including visual inspection, electrical testing, functional testing, and environmental testing.

Quality Assurance: Quality assurance measures should be incorporated throughout the fabrication and assembly process to ensure that the final product is of high quality. Visual inspection and automated optical inspection (AOI) can be used to check for defects and errors in the board. X-ray inspection can be used to check the quality of the plate through holes and other hidden features of the board.

Overall, a good PCB fabrication and assembly process should result in a high-quality, reliable product that meets the project’s requirements and performs as intended.